Flexible Modular Mobile Workbench

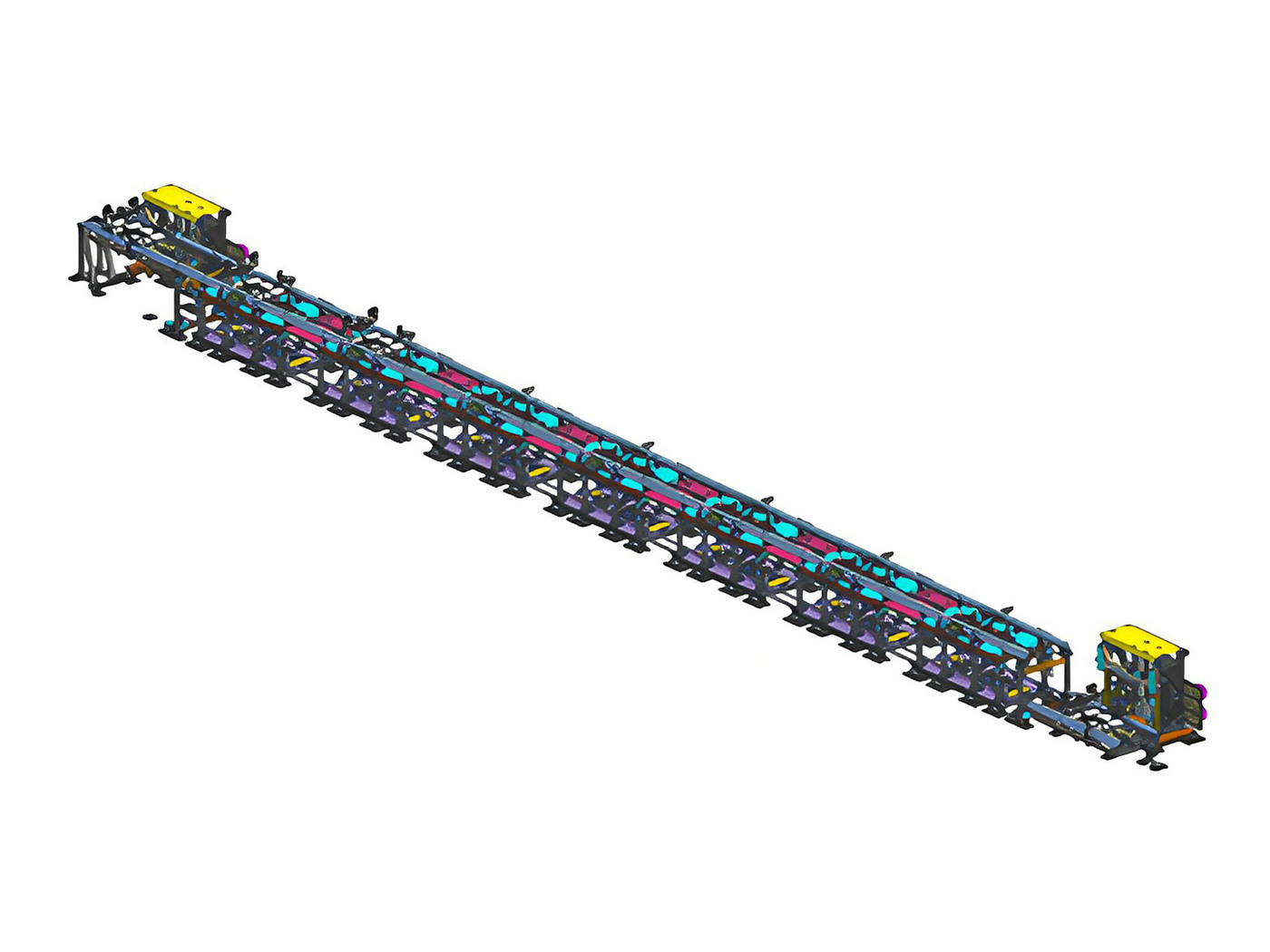

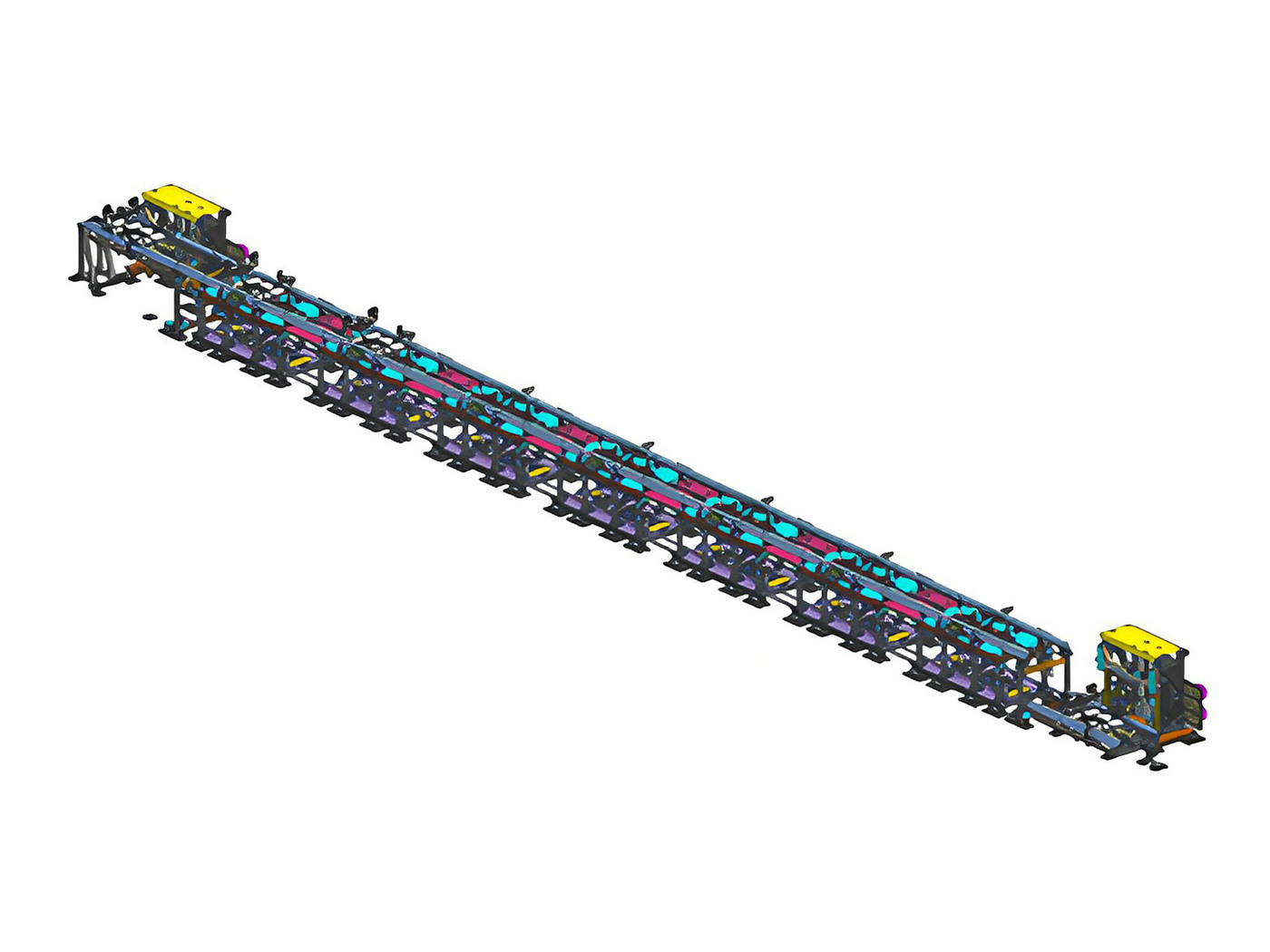

The flexible sub-assembly travelling carriage constitutes a pivotal piece of equipment in modern automotive welding production lines for achieving mixed-model production. Through an automated conveying and positioning system, it enables the assembly and welding of body components from different vehicle models on a single production line without requiring line stoppages for changeovers. The flexible sub-assembly travelling carriage system primarily integrates carriages, fixtures, conveyor lines, and robotic equipment. Its core function is to achieve flexible, automated assembly and welding of sub-assemblies (such as body side panels and floor panels).

| Product Features | |

|---|---|

|

● Suitable for inner and outer side panels, front and rear floor panels, and engine compartments ● Reliable repeatability: ±0.2mm ● High-speed travelling fixture, speed >1.2m/s ● Flexible bar-changing system accommodates multiple fixtures of equivalent capacity, enabling multi-model production on the same line ● 65JPH high-volume application: proven in over 8 million production vehicles ● Compact footprint |

|

|

Serial Number |

Vehicle Manufacturer |

Project Number |

Cycle Time |

Region |

|

1 |

SGM South Golden Bridge Plant |

E2LB |

60JPH |

Engine compartment, outer side panels |

|

2 |

SGM Jinqiao New Plant |

U358 & T261 |

40JPH |

Engine Bay |

|

3 |

SGM Dongyue South Plant |

K257 & 9YBY & 9BYC |

60JPH |

Engine room |

|

4 |

SGM Jinqiao North Plant |

C1UB & C1UC & G2KBZ |

50JPH |

Engine room |